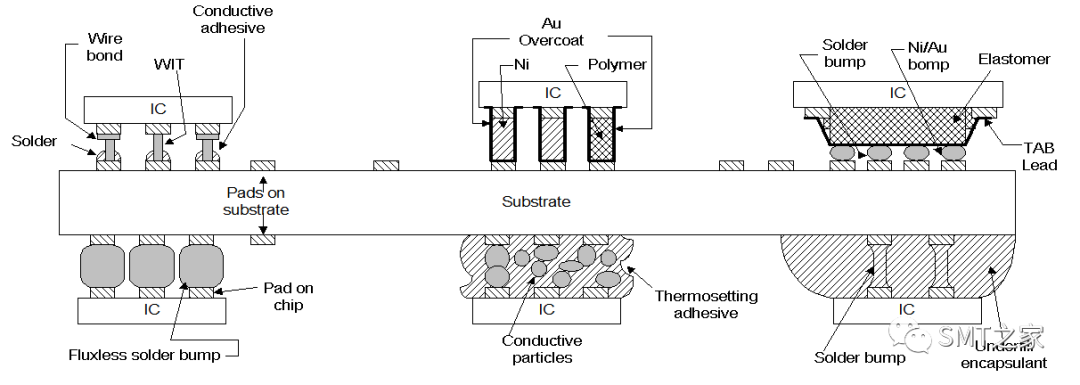

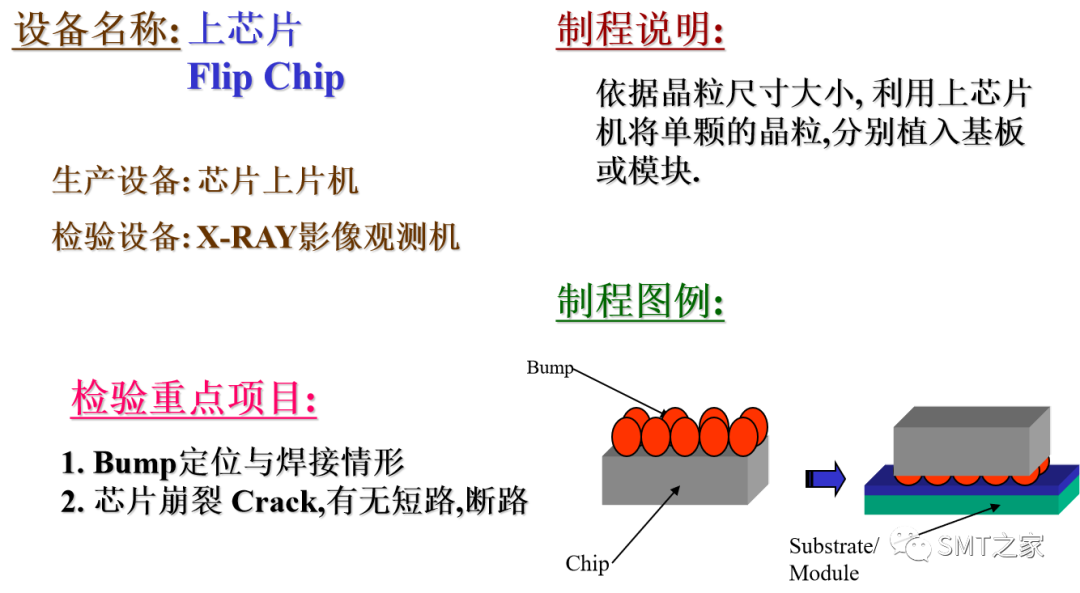

Flip Chip conductive method - connect to Substrate/PCB

1.Metal bump 金屬凸塊-C4 process(IBM)

2. Tape-Automated bonding 卷帶接合-ACF process

3. Anisotropic conductive adhesives

異方向性導(dǎo)電膠 -ACP process

4.Polymer bump 高分子凸塊 - C4 process

5.Stud bump. 打線成球 - ACP process(Matsushita)

C4: controlled collapse chip connection

ACF: anisotropic conductive film

ACP(ACA): anisotropic conductive Adhesive paste

Various flip chip technologies

PS: WIT ( Wire interconnect technology)

TAB(Tape- automated bonding)

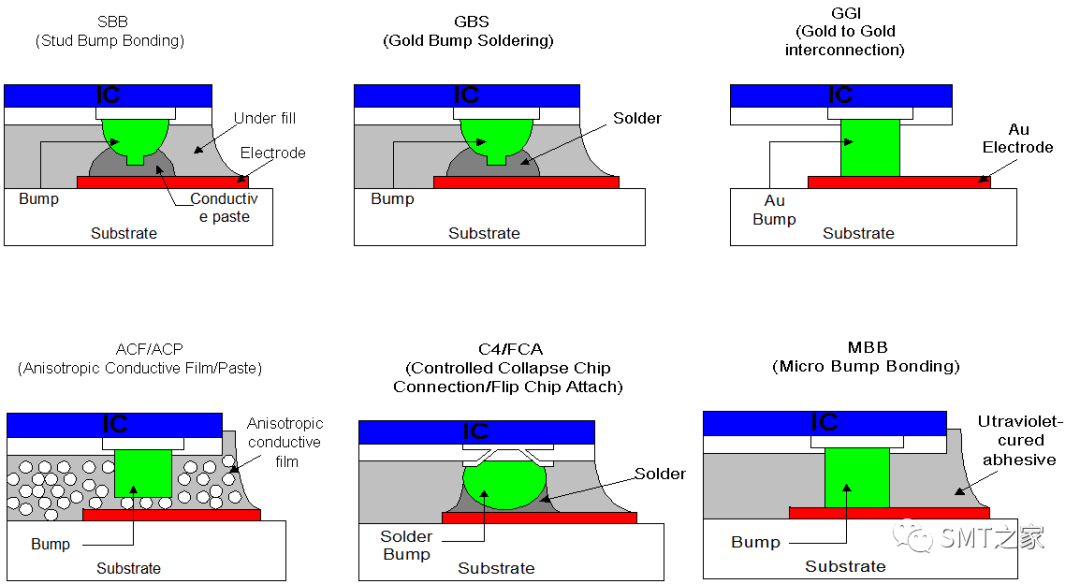

Various flip chip technologies

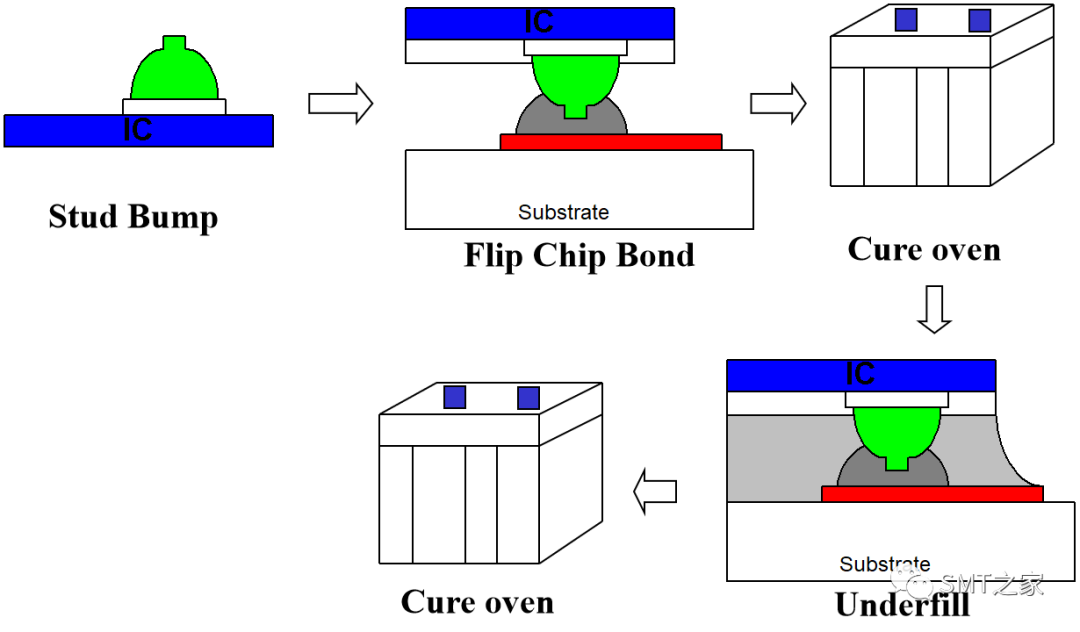

SBB Process

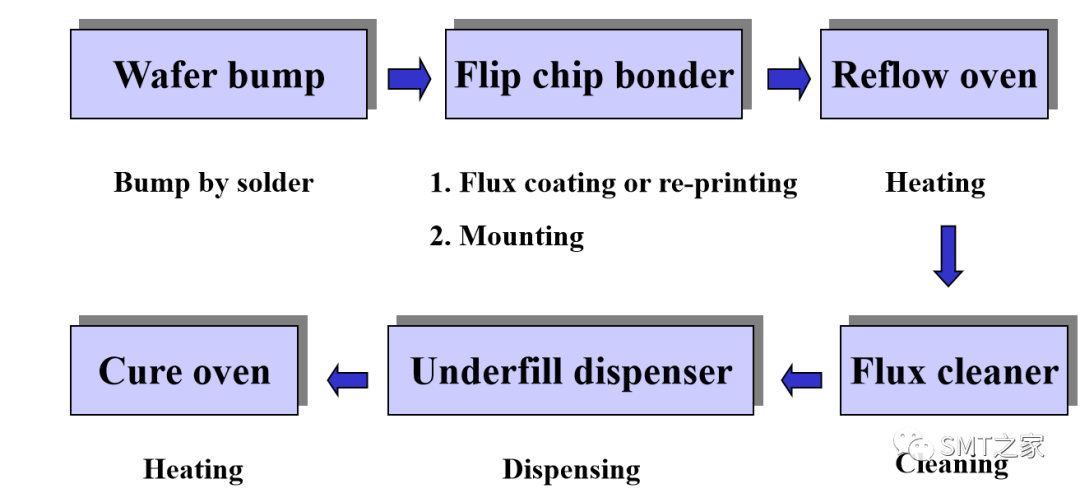

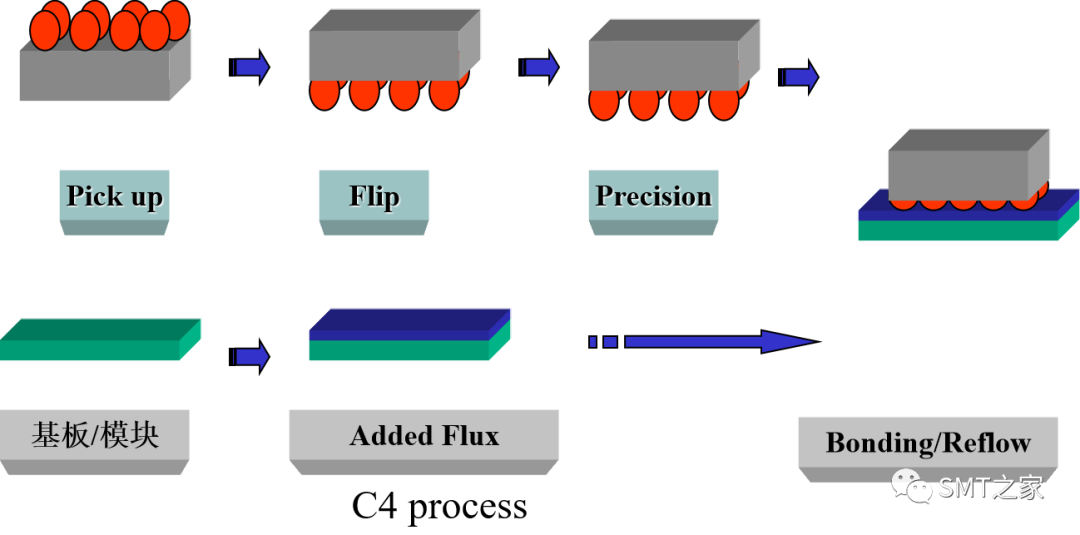

C4: Controlled Collapse Chip Connection Process

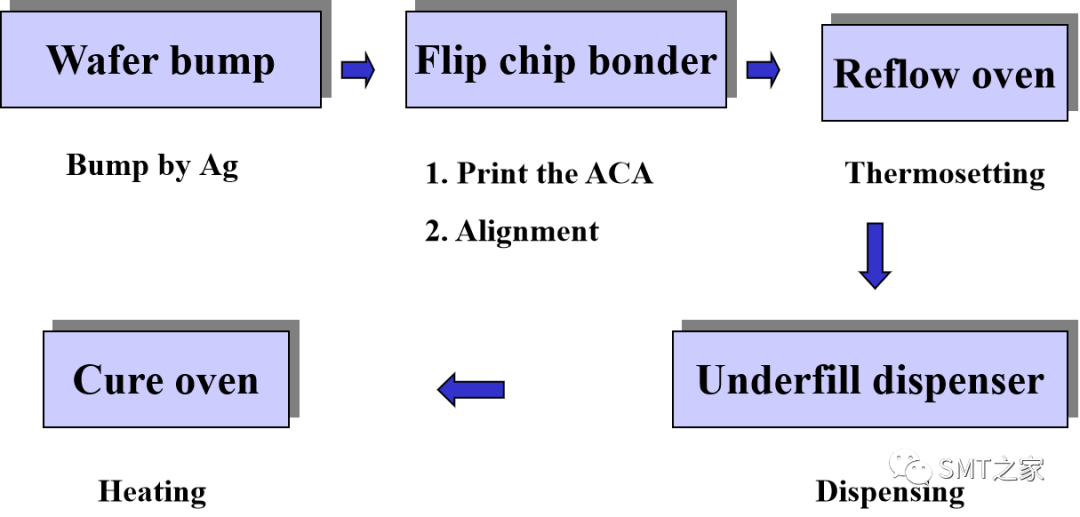

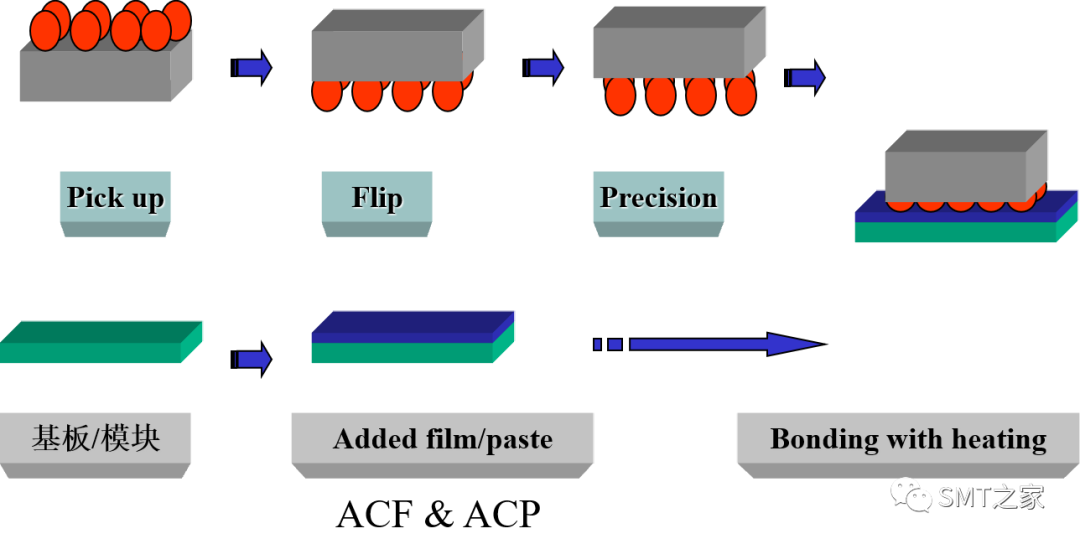

ACP: Anisotropic Conductive Paste Process

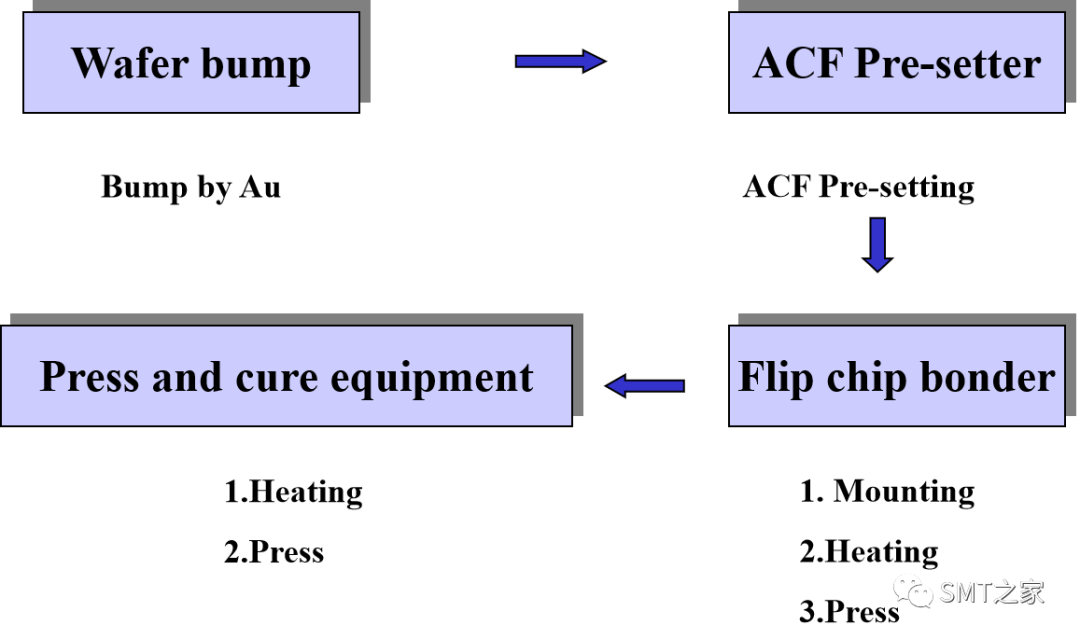

ACF: Anisotropic Conductive Film Process

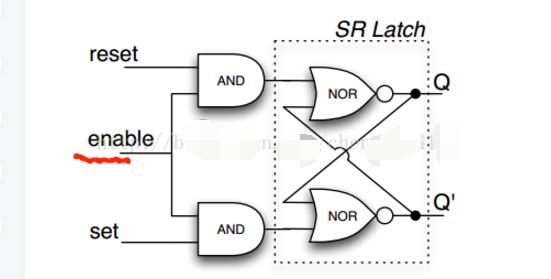

Wafer Bump

Metal bump method

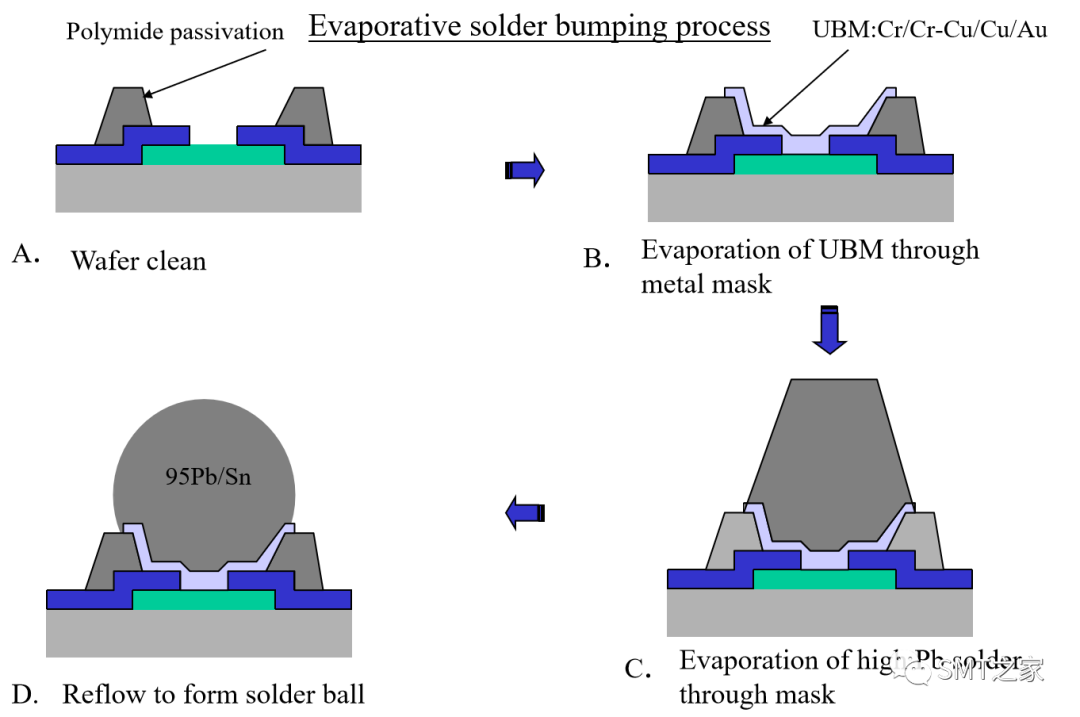

1. 蒸鍍 Evaporation?

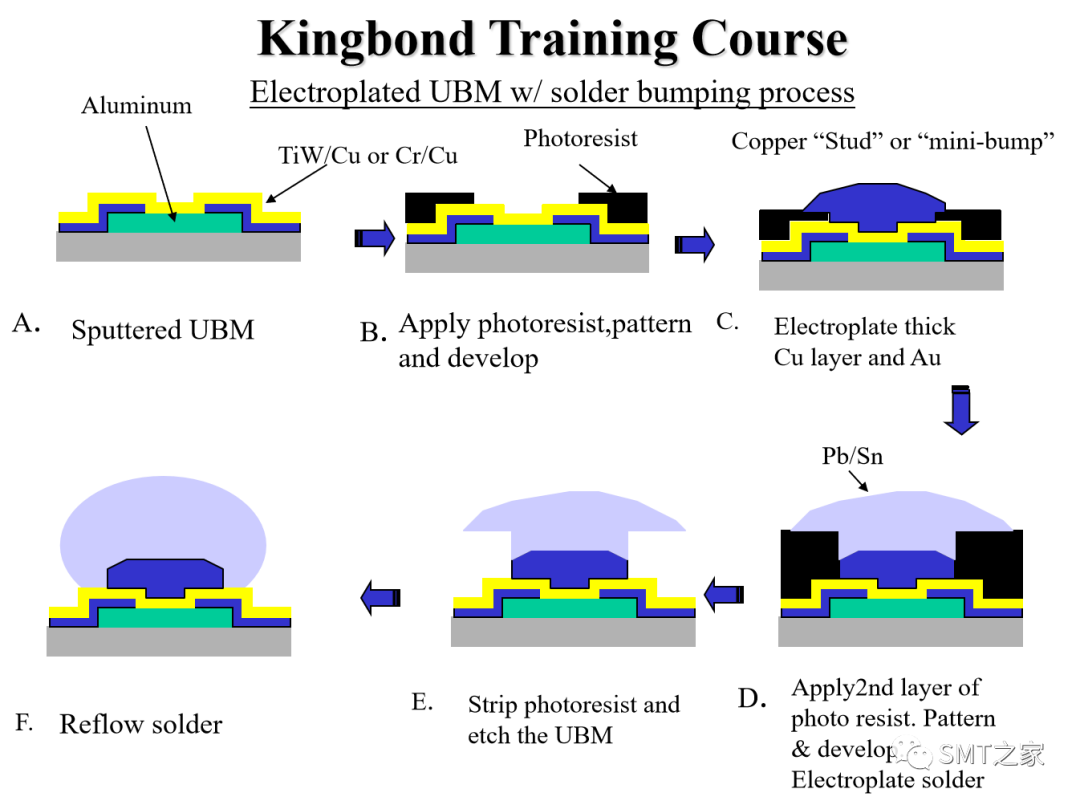

2. 濺鍍 Sputter?

3. 電鍍 Electroplating

4. 印刷 Printed solder paste bump

5. 錫球焊接 Solder ball bumping or Stud bump bonding (SBB)

6.無電鍍鎳 Electroless nickel technologies

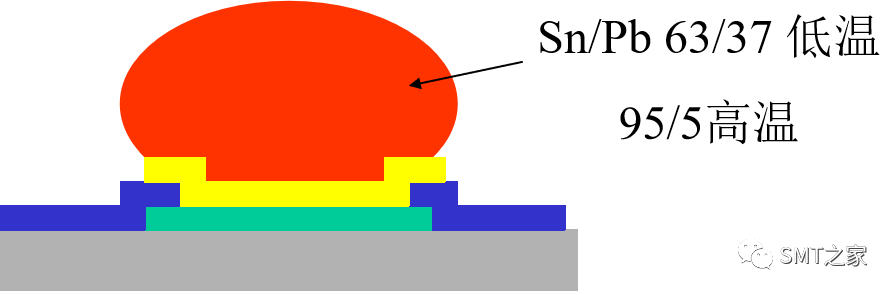

Material of solder bump

1.95Sn/5Pb,97Sn/3Pb 高溫錫鉛合金

2. 63Sn/37Pb 低溫錫鉛合金

3. Ni 鎳

4. Au 金?

5.Cu 銅

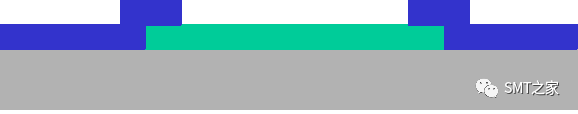

Wafer bump (Printed method) Process:Wafer clean

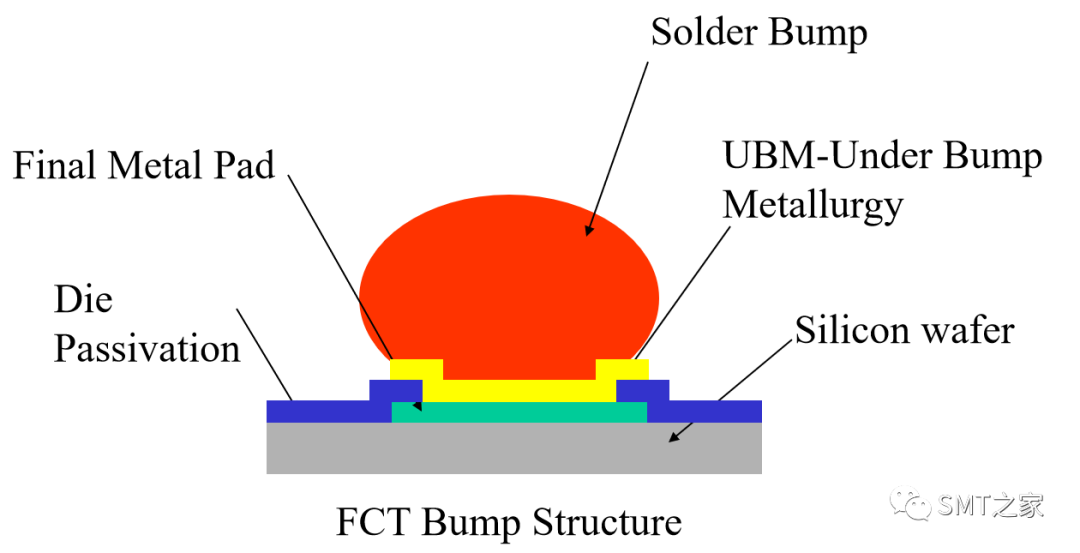

Silicon Wafer arrives with an aluminum based final metal pad and die passivation. Wafer can be probed prior to bumping.

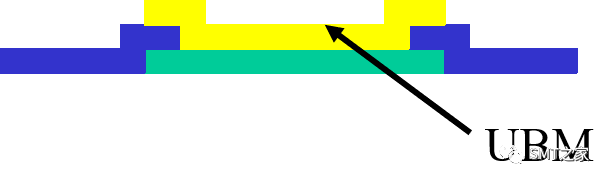

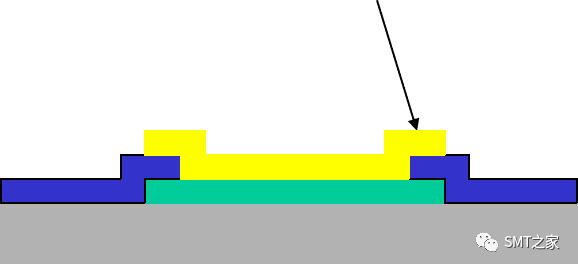

Wafer Bump (Printed method)?Process: Sputter UBM

The Under Bump Metallurgy is added by FCT through sputtered layers of Al,Ni-V,&Cu

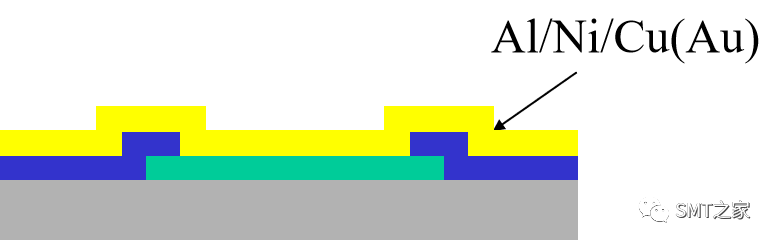

Wafer Bump (Evaporation method)

Process: Sputter UBM

UBM consist 3 layer:

1. Adhesion layer : Ti,Cr,TiW 提供鋁墊(Al pad)與護(hù)層(Passivation layer)有較強(qiáng)之黏著性

2. Wetting layer:Ni,Cu,Mo,Pt 高溫回焊時(shí)錫球可完全沾附而成球

3. Protective layer:Au 保護(hù) Ni,Cu等免于被氧化.

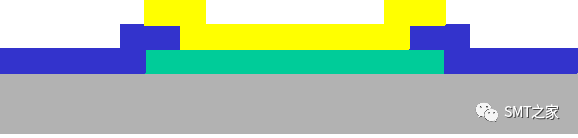

Wafer Bump (Printed method)

Process:Photo-resist

Apply photoresist, Pattern and develop

Wafer Bump (Printed method)

Process: Etch UBM

Etch to form UBM cap

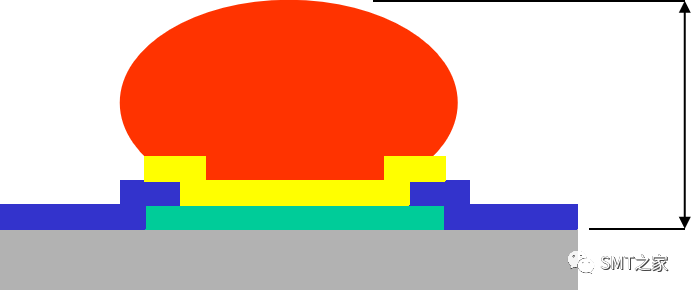

Wafer Bump (Printed method)?

Process: Print solder paste & reflow

Deposit solder paste and reflow to form bump

Wafer Bump (Printed method)

Process: Inspection

Sample measure bump height, bump shear and bump resistance.

The typical size of a bump before reflow :

1. Evaporative bumps are 125 mils in diameter and 100 mils high.

2. Plated bumps are 125 - 175 mils in diameter and 25 -100 mils high.

上芯片流程Flip Chip flow

上芯片流程Flip Chip flow

Why do you need to underfill

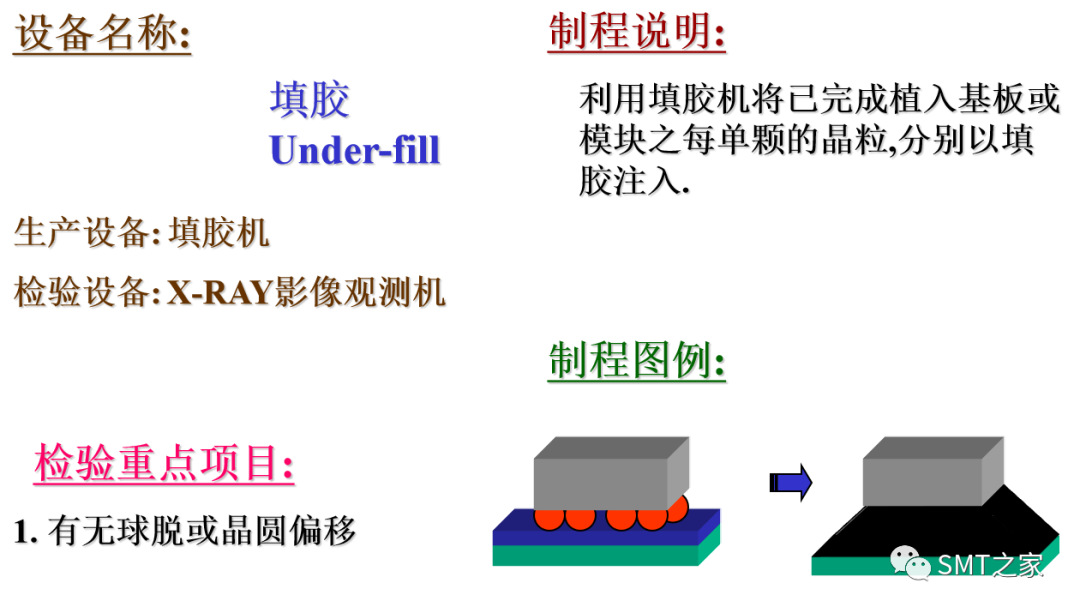

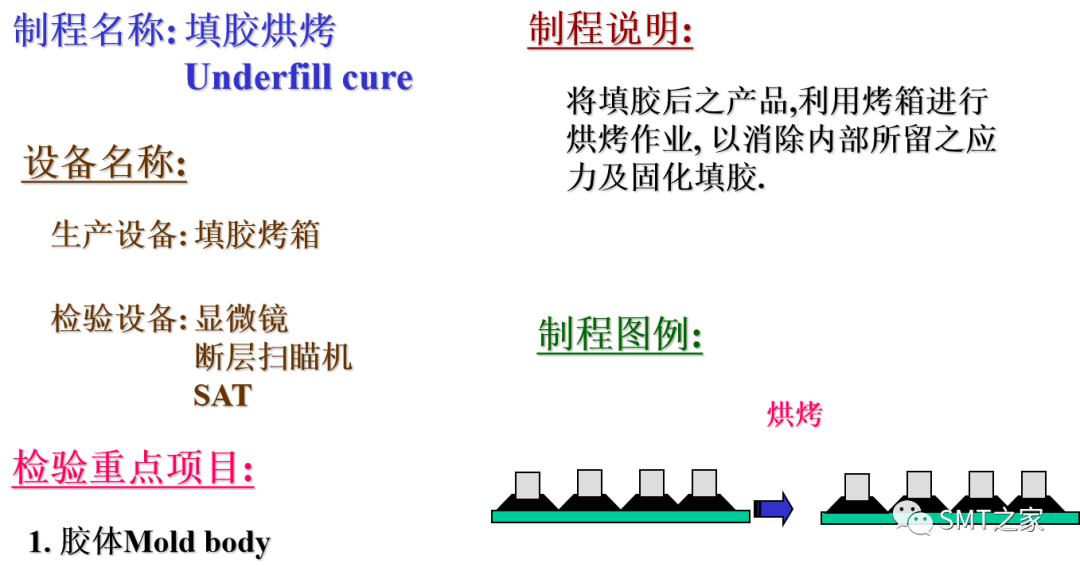

填膠制程? Under-fill

1. 毛細(xì)作用型 Capillary type):

利用毛細(xì)力造成膠材之流動(dòng).

2. 異方向?qū)щ娔z(Anisotropic conductive adhesive):

低溫制程,分膏狀(paste)和膜狀(film)

3. 前置型(Pre-applied type):

小尺寸芯片(<6mm),點(diǎn)膠(Die attachment)后再回焊(Reflow)

制程與材料之限制:

1. 加強(qiáng)快速填膠與固化能力

2. 提升其界面之黏著力

3. 較低的吸水率

4. 提升低錫鉛球間距內(nèi)的流動(dòng)性

5. 加強(qiáng)可重工性(rework)

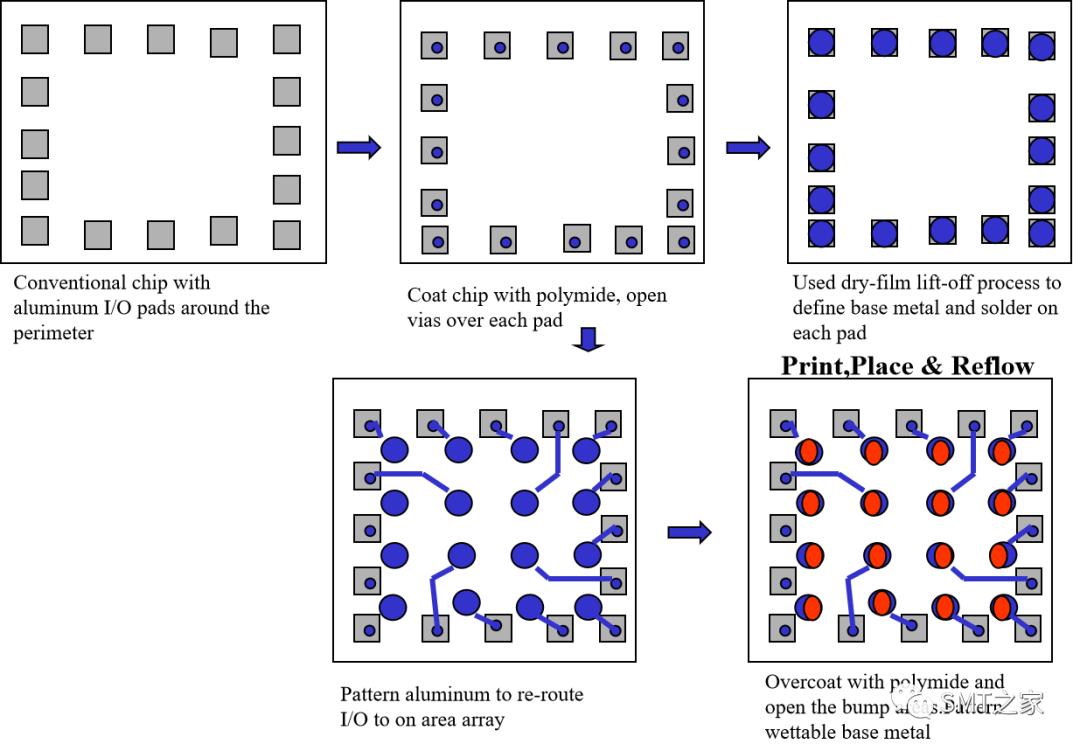

Polymide passivation?Evaporative solder bumping process

UBM:Cr/Cr-Cu/Cu/Au

編輯:黃飛

?

電子發(fā)燒友App

電子發(fā)燒友App

評(píng)論